The Integral Role of Shims: Torque vs Turn Axle

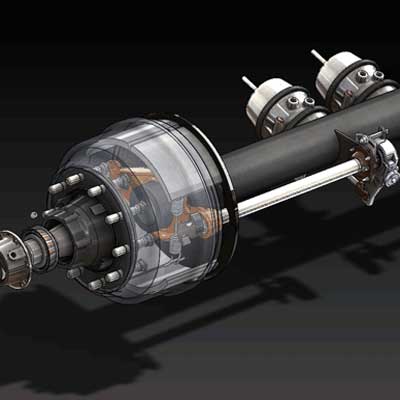

The world of mechanics is a vast, complex realm that is constantly evolving and adapting. One of the most critical aspects of this field is understanding the dynamics of torque and turn axle. The term ‘torque’ refers to the force that causes an object to rotate around an axis. On the other hand, ‘turn axle’ refers to the pivot point around which the rotation occurs. Understanding the interplay between these two elements is essential in many mechanical applications, ranging from automotive engineering to industrial machinery.

The relationship between torque and turn axle is not a straightforward one. It involves an intricate balance that requires precision and accuracy. In this context, the term ‘torque vs turn’ is used to describe the relationship between the amount of force applied (torque) and the degree to which the axle turns. This relationship is influenced by various factors, including the design of the axle, the materials used, and the presence of certain components like shims.

Understanding this relationship is crucial because it can greatly impact the performance and efficiency of machinery. A slight misalignment or imbalance in the torque vs turn axle can lead to significant problems, such as increased wear and tear, reduced performance, and even complete system failure.

The Importance of Shims in Torque vs Turn Axle

The importance of shims to torque vs turn axle cannot be overstated. Shims are thin pieces of material, often metal, used to fill small gaps or spaces between objects. In the context of torque vs turn axle, they play a crucial role in maintaining the balance and alignment of the system.

Shims help to ensure that the axle is positioned correctly, thereby ensuring that the torque is applied effectively. They can also be used to adjust the level of torque, allowing for fine-tuning of the system’s performance. Furthermore, shims can help to reduce wear and tear on the axle, thereby extending its lifespan.

The use of shims in torque vs turn axle is a delicate process that requires precision and expertise. Incorrect placement or use of shims can lead to misalignment and imbalance, which can have serious consequences. Therefore, it’s essential to understand the role of shims in this context and to use them correctly to ensure the optimal performance of the system.

Precision Shims: Essential Component in Torque vs Turn

Precision shims are a specific type of shim designed for use in applications that require a high degree of accuracy and precision. They are typically made from high-quality materials and are precision-engineered to exact specifications. This ensures that they provide the perfect fit and alignment in the system, thereby optimizing the torque vs turn axle’s performance.

In the context of torque vs turn axle, precision shims play an integral role. They help to maintain the correct alignment of the axle, ensuring that the torque is applied effectively. They also allow for fine-tuning of the torque level, enabling the system to operate at its optimal efficiency.

Precision shims also have a protective role. They help to reduce wear and tear on the axle, preventing premature failure and extending the system’s lifespan. By ensuring the proper alignment and balance of the axle, they can also help to prevent damage to other components in the system.

Deeper Understanding of Precision Spacers

Precision spacers, like precision shims, are an essential component in torque vs turn axle. They are used to create a precise distance or gap between components, ensuring proper alignment and balance in the system.

In the context of torque vs turn axle, precision spacers play a critical role. They help to ensure that the axle is positioned correctly, which is crucial for the effective application of torque. They also allow for adjustments in the torque level, enabling the system to perform optimally.

Precision spacers also help to protect the axle from wear and tear. By maintaining proper alignment and balance, they reduce the risk of premature failure and extend the system’s lifespan. Furthermore, they can help to prevent damage to other components in the system, enhancing its overall performance and efficiency.

Role of Precision Setting in Torque vs Turn Axle

Precision setting is a crucial aspect of torque vs turn axle. It involves the careful placement and adjustment of components like shims and spacers to ensure optimal performance. This requires a high degree of accuracy and precision, as even slight misalignments or imbalances can have significant consequences.

In the context of torque vs turn axle, precision setting plays a vital role. It ensures that the axle is positioned correctly, which is key to the effective application of torque. It also allows for fine-tuning of the torque level, enabling the system to operate at its optimal efficiency.

Precision setting also has a protective role. It helps to reduce wear and tear on the axle, thereby extending its lifespan. By ensuring the proper alignment and balance of the axle, it can also help to prevent damage to other components in the system.

The Science Behind Torque vs Turn Axle and Shims

The science behind torque vs turn axle and shims is a complex one. It involves understanding the principles of mechanics, material science, and engineering. At its core, it’s about understanding the relationship between force (torque) and rotation (turn axle), and how this relationship is influenced by various factors, including the design of the axle, the materials used, and the presence of components like shims.

Shims play a crucial role in this relationship. They help to maintain the balance and alignment of the system, ensuring that the torque is applied effectively. They can also be used to adjust the level of torque, allowing for fine-tuning of the system’s performance.

The science behind this is complex, involving a deep understanding of the properties of the materials used, the dynamics of force and motion, and the principles of engineering. However, by understanding this science, one can optimize the performance of the system and ensure its longevity.

How Precision Shims Impact Torque vs Turn Axle Performance

Precision shims have a significant impact on torque vs turn axle performance. By maintaining the correct alignment of the axle, they ensure that the torque is applied effectively. They also allow for adjustments in the torque level, enabling the system to operate at its optimal efficiency.

Furthermore, precision shims help to protect the axle from wear and tear. By maintaining proper alignment and balance, they reduce the risk of premature failure and extend the system’s lifespan. They can also help to prevent damage to other components in the system, enhancing its overall performance and reliability.

However, the impact of precision shims on performance is not solely positive. If not used correctly, they can lead to misalignments and imbalances, which can have serious consequences. Therefore, it’s crucial to understand the role of precision shims in this context and to use them correctly.

The Correct Use of Precision Spacers in Torque vs Turn Axle

The correct use of precision spacers in torque vs turn axle is crucial. Like precision shims, they play a vital role in maintaining the balance and alignment of the system. They ensure that the axle is positioned correctly, which is key to the effective application of torque. They also allow for adjustments in the torque level, enabling the system to perform optimally.

Precision spacers also have a protective role. They help to reduce wear and tear on the axle, thereby extending its lifespan. By maintaining proper alignment and balance, they can also help to prevent damage to other components in the system.

However, the correct use of precision spacers is not straightforward. It requires a deep understanding of the system and its components, as well as expertise in mechanics and engineering. Incorrect placement or use of spacers can lead to serious consequences, so it’s crucial to ensure that they are used correctly.

Case Studies: Precision Setting on Torque vs Turn Axle Performance

The impact of precision setting on torque vs turn axle performance is well-documented in various case studies. These studies highlight the crucial role of precision setting in maintaining the balance and alignment of the system, and in ensuring its optimal performance.

One case study, for example, found that precision setting significantly improved the performance of a torque vs turn axle system in an industrial machinery application. The researchers found that by carefully setting the shims and spacers, they were able to optimize the torque application, resulting in improved efficiency and longevity of the system.

Another case study highlighted the protective role of precision setting. The researchers found that by maintaining proper alignment and balance, precision setting helped to reduce wear and tear on the axle, thereby extending its lifespan. It also helped to prevent damage to other components in the system, enhancing its overall performance and reliability.

Shim Manufacturing | Michigan

In conclusion, shims play an indispensable role in torque vs turn axles. They are critical in maintaining the balance and alignment of the system, ensuring that the torque is applied effectively. They also allow for adjustments in the torque level, enabling the system to operate at its optimal efficiency.

Furthermore, shims help to protect the axle from wear and tear. By maintaining proper alignment and balance, they reduce the risk of premature failure and extend the system’s lifespan. They can also help to prevent damage to other components in the system, enhancing its overall performance and reliability.

However, the role of shims in torque vs turn axle is not a straightforward one. It requires a deep understanding of the system and its components, as well as expertise in mechanics and engineering. Therefore, it’s crucial to ensure that shims are used correctly and that precision setting is employed to optimize the system’s performance.

For those in need of precision shims, precision spacers, or advice on precision setting, Northern Industrial Manufacturing is a trusted provider. With a range of high-quality products and a team of experienced professionals, they are well-equipped to meet your needs. So, don’t hesitate, reach out to Northern Industrial Manufacturing shims today. Your machinery will thank you!

Shim Manufacturing | Michigan: 586-468-2790

Thank you for visiting our blog where we keep you updated on the latest News and Events in automotive manufacturing!

Please check back often to learn what is going on with Northern Industrial Manufacturing, in the world of precision thrust washers, selective shims, and spacers.